Metal-coated microspheres are used as catalysts, laser fusion targets, and materials for preparing:

- electrically conductive adhesives and polymers

- composites and reinforced polymers

- Cu and Ag pastes for electronics

- thermoelectrical elements

- ablative coatings

- electrically conducting bond line spacers

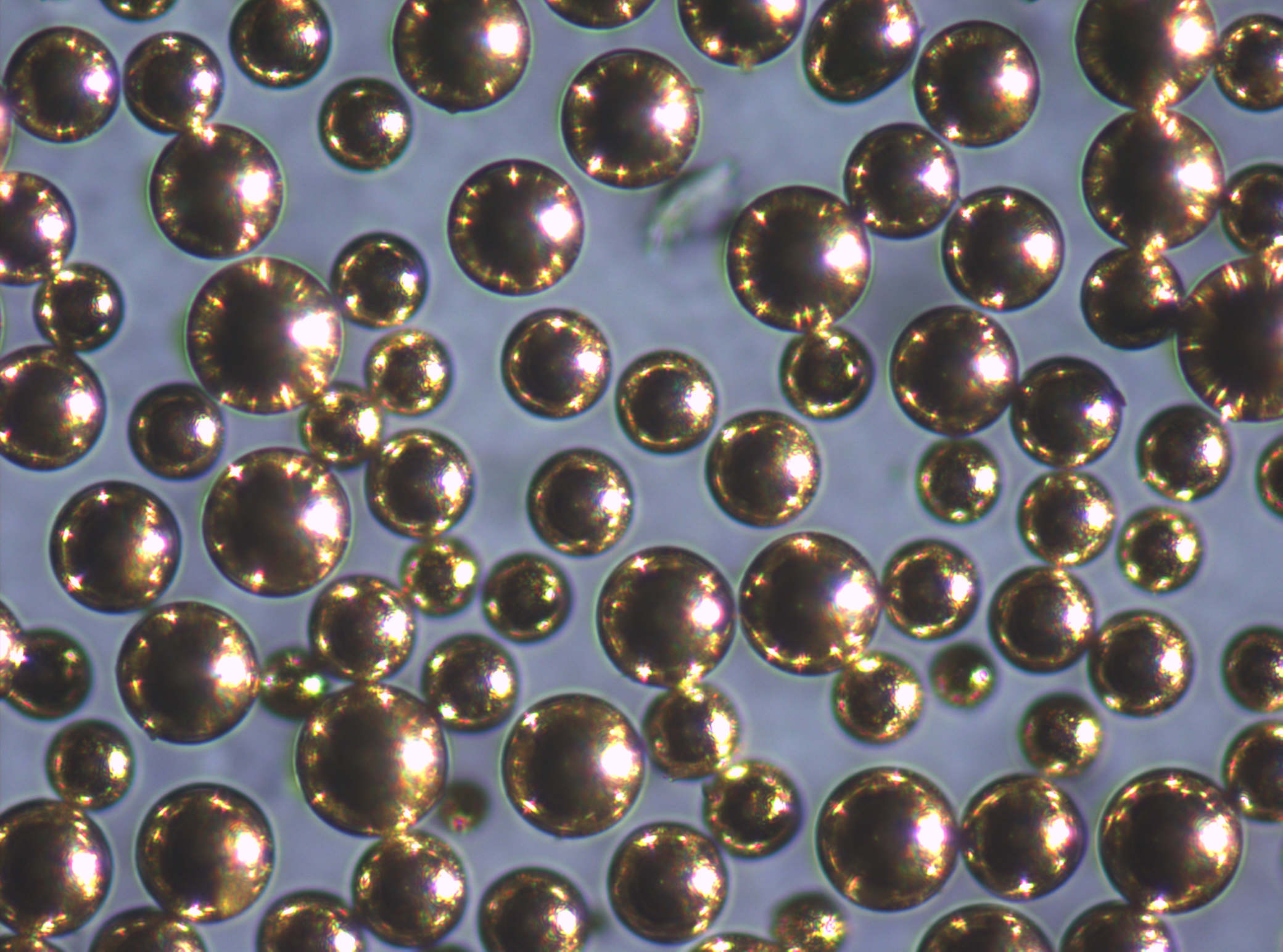

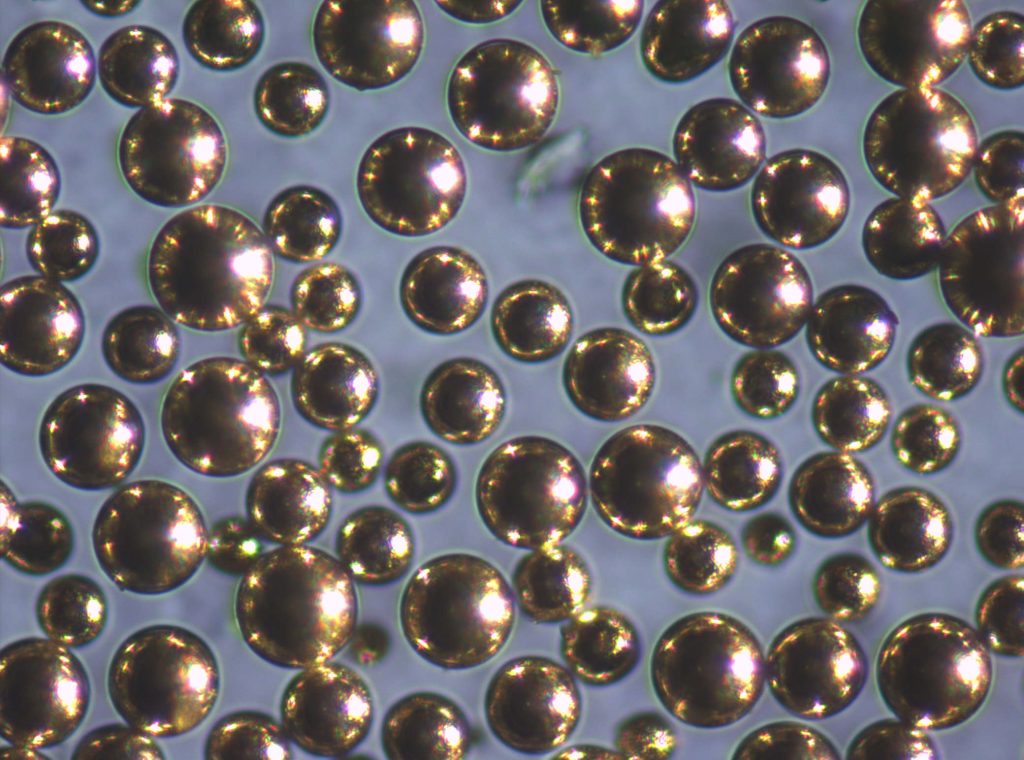

Metal-coated microspheres are manufactured by electroless autocatalytic deposition of metals or metal alloys on all types of dense or porous glass (e.g., soda lime, silica, borosilicate, and aluminosilicate) microspheres ranging from 1-1000 µm in diameter.

Coating metals are Ni, Cu, Ag, and Au. Multilayer metal coatings consisting of different metals/alloys can also be produced. The adhesion of the metal coating to the glass substrate is excellent; the metal coating does not defoliate during processing or with ultrasonic treatment.

Metal-coated microspheres are free of metal particles, or uncoated glass microspheres. The properties of the metal coating are close to those of the bulk metal.

The metal coating can provide the following properties to the glass substrate:

- high electrical conductivity

- high thermal conductivity

- chemical resistance

- catalytic and electrocatalytic activity

- ferromagnetism

- high specific weight

- mechanical strength

- electromagnetic absorption

- Metal coatings with similar properties can also be deposited on all types of glass fibers.

Mo-Sci has extensive experience manufacturing glass microspheres and fibers. We also develop glass compositions whose properties are tailor-made to satisfy particular applications. If you need a special glass frit, glass microsphere spacer or desire further information, contact our office and one of our engineers will be happy to discuss our products and services with you.