Biomaterials

Bioactive glasses have the ability to bond to soft and/or hard tissue and are biodegradable in the body. The release of ions and the formation of hydroxyapatite support the regeneration of bone tissue and can accelerate the healing process.

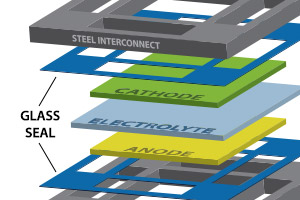

Sealing Glass

Sealing glasses function as high-temperature sealant materials for solid oxide fuel cells (SOFCs) and other applications such as sodium-ion batteries.

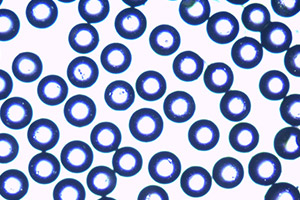

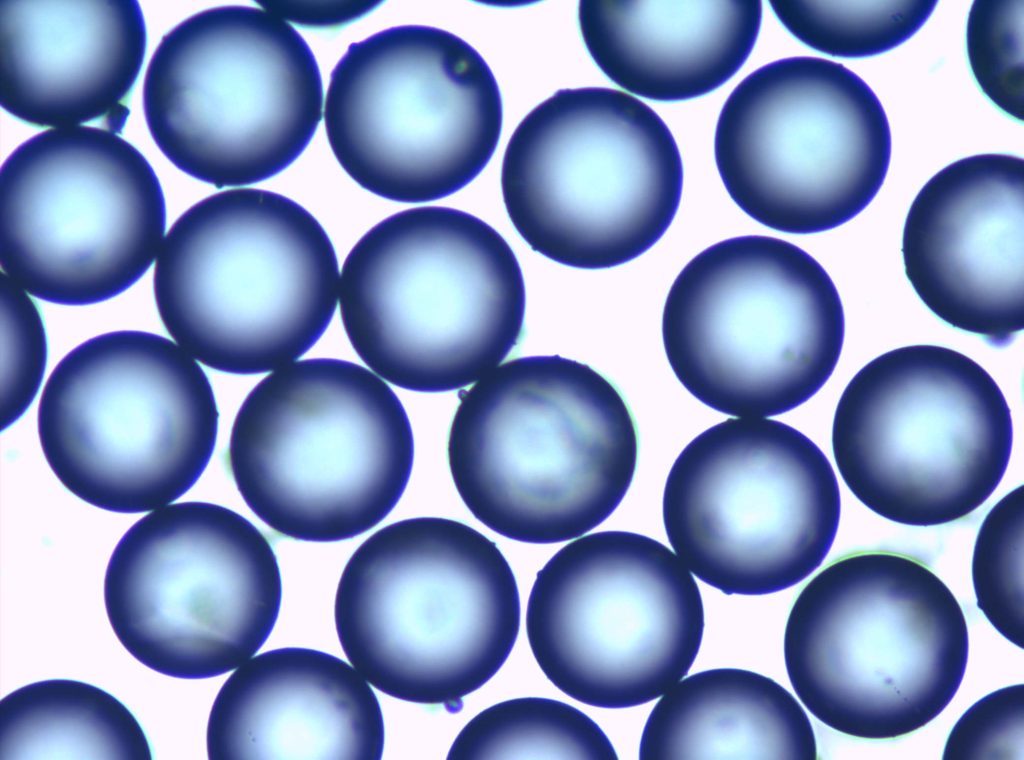

Glass Microspheres

Glass microspheres can be manufactured to industrial-grade (Class IV), engineering-grade (Class V), and spacer-grade (Class VI) specifications depending on the tolerance requirements of the application.

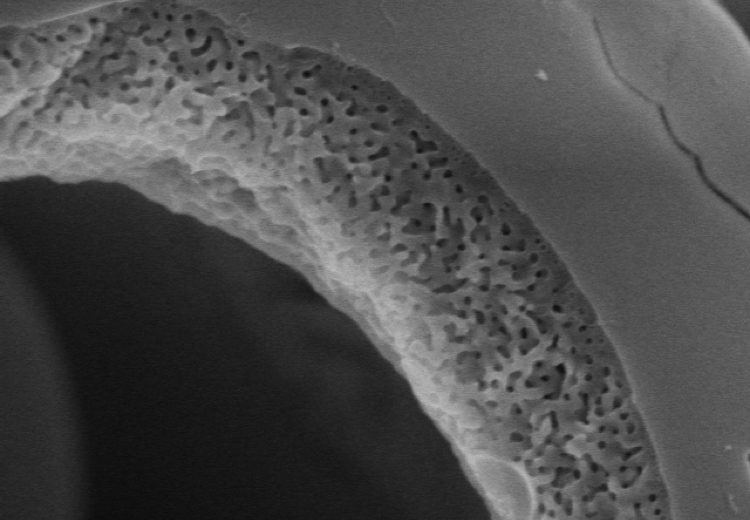

Porous Silica

Porous silica glasses are resistant to acidic conditions and can be used for a variety of applications from chromatography, a carrier for the release of liquids, an absorber for liquids, and thermal barrier protection.

Fluorescent Glass

Fluorescent glass can be tailor-made to uniquely identify the manufacturer and lot number for many types of products, particularly powders, plastics, papers, and liquids.

Order trial quantities online

Jump-start your product development with sample quantities of our standard glass products.