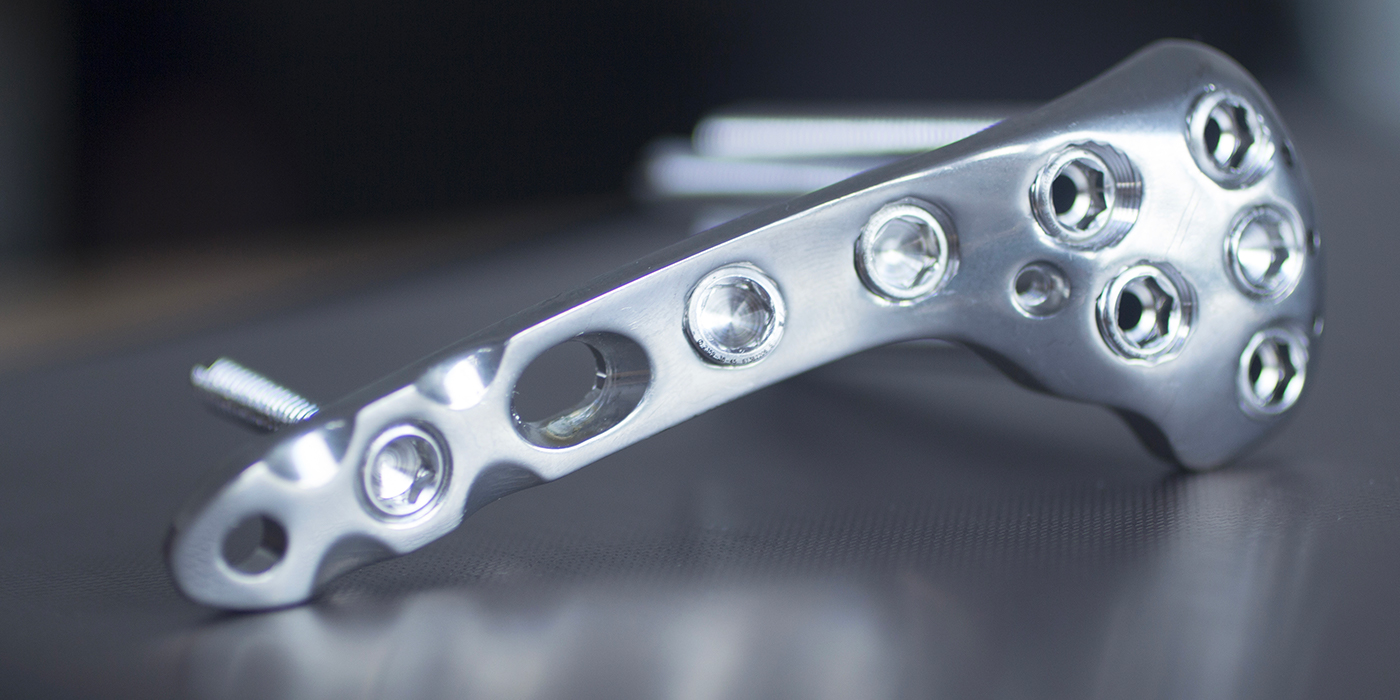

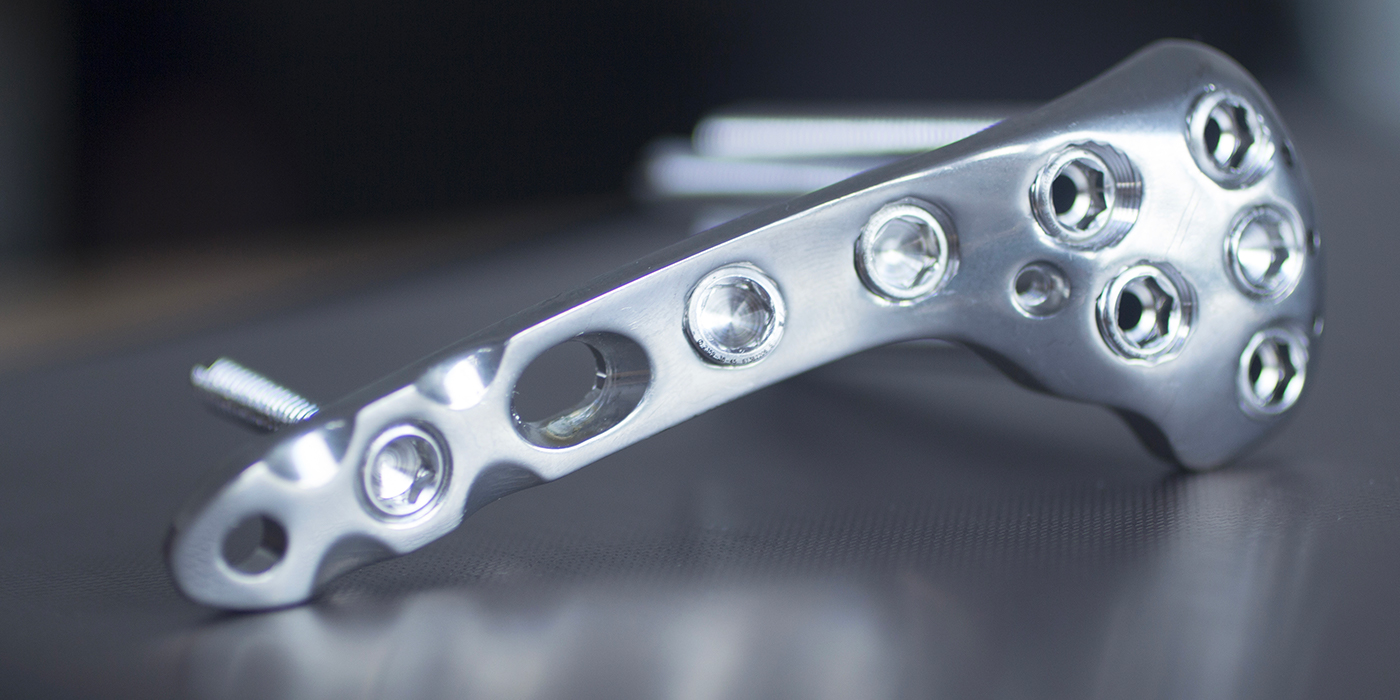

Disease, trauma or serious infection may result in extensive bone damage or bone loss which exceeds the body’s capacity to repair itself. In such cases, implants are needed to promote satisfactory healing. These may take the form of screws, plates, or rods to immobilize broken bones in the correct alignment, reinforce weak bones or correct skeletal deformities. Similarly, diseased joints can be replaced with prosthetic joints to restore normal, pain-free movement.

Despite ongoing medical advances and improvements in materials and procedures, there remains a substantial risk of implanted devices becoming infected. In addition to microbes being introduced into the body during surgery, there is the risk of bacteria transported in the blood from other parts of the body colonizing the surface of an implant. It has been estimated that as many as 2.5% of primary hip and knee replacements and to 10% of joint revision surgeries are complicated by infection.1 Infected implanted devices represent a significant clinical challenge. Typically, despite lengthy antibiotic treatments, it is often necessary for the infected implant to be surgically removed. This not only increases patient morbidity and dissatisfaction, but is also associated with substantial cost.2

Antibiotics continue to be the mainstay strategy for both the prevention and treatment of implant infections. However, the power of antibiotics in the fight against infection is diminishing as many strains of potent bacteria are developing resistance to even the strongest antibiotics. Consequently, the risk of implanted devices becoming infected is on the rise and researchers are investigating novel ways to reduce such infections.

One strategy is based on the discovery that the majority of bacteria live in surface-bound microbial communities, rather than as free-swimming entities. On binding to the surface, bacteria secrete adhesion proteins that provide an irreversible attachment.3 Such bacterial biofilms account for over 80% of clinical microbial infections.2 It was therefore proposed that making the surface of implants unsuitable for bacterial colonization would dramatically lower infection rates. This can be achieved by coating the implant with bioactive glass.

The Antimicrobial Properties of Bioactive Glass

Bioactive glass is a type of glass made from high-purity chemicals, such as silica, calcium, and boron, which induce specific biological activity.4 Bioactive glass, by virtue of its high strength, low weight and biocompatibility, has been widely used in a range of biomedical applications, including tissue engineering, bone grafting, dental reconstruction and wound healing.5

Such clinical experience has shown that borate bioactive glass possesses antimicrobial properties against a wide range of bacteria, including MRSA and E-coli.6,7 The antimicrobial efficacy is achieved though an increase in pH of the surrounding body fluids (which is stressful for bacteria) and because any bacteria that do approach are unable to adhere to bioactive glass and so cannot create microfilms on its surface.8,9 In vitro studies have confirmed that bioactive glass has strong anti-staphylococcal and anti-streptococcal activity.10,11

Since the antimicrobial action of bioactive glass arises from it creating an environment that is hostile to bacteria rather than requiring direct contact with the invading microbe in order to kill it, it is effective across a wide range of bacteria. Furthermore, the bacteria cannot adapt to such effects, and so no bacteria have been found to develop resistance to the antimicrobial effects of bioactive glass.9

Coating Implants with Bioactive Glass

Initial technical challenges have been overcome and a range of titanium implants have been successfully coated with bioactive glass.12 Clinical use of implants coated with bioactive glass has given promising results in both orthopedic and dental applications. There was no evidence of the coated implants causing any adverse effects or inflammatory response in the surrounding tissue. Furthermore, the implants coated with bioactive glass were found to accelerate cell attachment and mineralization of the extracellular matrix, promoting more rapid bone growth. In addition, the proportion of bone-to-implant contact was significantly greater for implants coated with bioactive glass compared with traditional implants.13-15

Enhancing the Antimicrobial Efficacy of Bioactive Glass

Bioactive glass has good antimicrobial action, being effective against a broad spectrum of aerobic and anaerobic bacteria.9 However, the antimicrobial effects can be further enhanced to increase the range of antimicrobial activity, by the addition of ions, such as boron, copper, silver, yttrium, and iodine, or organic nanoparticles.16,17 The chosen antimicrobial agent is incorporated into the bioactive glass during its production and released once the bioactive glass is in an aqueous solution, creating an environment inhospitable for microbial life. The bioactive glass can thus be used as a delivery system for antimicrobials.18

The advantage of ions and nanoparticles over antibiotics is that their efficacy depends solely on contact with the bacterial cell wall; they do not need to enter the cell. Consequently, their lethal effect is delivered irrespective of the specific genetics of the target bacteria and is unaffected by the resistance mechanisms used by bacteria to evade antibiotics.

Conclusion

Infection of medical implants is an increasingly serious clinical and socioeconomic burden. Furthermore, the situation is likely to worsen with the increasing prevalence of bacteria with multi-drug resistance.

Bioactive glass has inherent antimicrobial activity and does not elicit a toxic response to surrounding tissues. Consequently, coating implants with bioactive glass represents an attractive option for reducing the risk of infection. The antimicrobial properties of bioactive glass can be further enhanced by loading it with antimicrobial agents, such as ions or antibacterial nanoparticles. Such a strategy would reduce the need for prophylactic antibiotic use, whereby protecting against the development of further strains of antibiotic-resistant bacteria.

Since bacteria cannot adapt to the hostile environment created by bioactive glass or its biofilm-resistant surface, they are unlikely to develop resistance to the antimicrobial action of bioactive glass.

In addition, the coating of implants with bioactive glass has been shown to speed up the fusion of the implant with bone, accelerating a patient’s recovery.

The use of bioactive glass, either alone or doped with antimicrobial agents, as a coating for orthopedic and dental implants is thus likely to improve the success rate and enhance patient outcomes across a range of reparative and restorative surgeries by promoting rapid healing and minimizing the occurrence of infection.

Mo-Sci produces high quality bioactive glass powders, the precise composition of which can be tailored to meet specific requirements. They produce bioactive glass suitable for coating orthopedic and dental implants.

References & Further Reading

- Lentino JR. Prosthetic joint infections: Bane of orthopedists, challenge for infectious disease specialists. Clin Infect Dis. 2003;36:1157–61. doi: 10.1086/374554.

- Hall-Stoodley L, et al. Bacterial biofilms: from the natural environment to infectious diseases. Nature Reviews Microbiology2004;2(2): 95–108.

- Davey ME and O’Toole GA. Microbial biofilms: from ecology to molecular genetics. Microbiology and Molecular Biology Reviews2000;64(4):847–867.

- Brauer DS. Bioactive Glasses—Structure and Properties. Angew Chem Int Ed 2015;54: 4160–4181.

- Rahaman MN, et al. Bioactive glass in tissue engineering. Acta Biomaterialia 2011;7:2355?2373.

- Ottomeyer M, et al. Broad-Spectrum Antibacterial Characteristics of Four Novel Borate-Based Bioactive Glasses. Advances in Microbiology 2016;6:776?787.

- Khvostenko D, et al. Bioactive glass fillers reduce bacterial penetration into marginal gaps for composite restorations. Dental materials 2016;32(1):73–81. Available at http://www.demajournal.com/article/S0109-5641(15)00437-6/pdf

- Zhang D, et al. Factors Controlling Antibacterial Properties of Bioactive Glasses. Key Engineering Materials 2007;330-332:173?176.

- Drago L, et al. Recent Evidence on Bioactive Glass Antimicrobial and Antibiofilm Activity: A Mini-Review Materials 2018;11:326?337.

- Misra SK, et al. Poly(3-hydroxybutyrate) multifunctional composite scaffolds for tissue engineering applications. Biomaterials 2010;31:2806–2815.

- Rivadeneira J, et al. In vitro antistaphylococcal effects of a novel 45S5 bioglass/agar-gelatin biocomposite films. J Appl Microbiol 2013;115,604–612.

- Lopez-Esteban S, et al. Bioactive glass coatings for orthopedic metallic implants. Journal of the European Ceramic Society 2003;23:2921–2930.

- Mehdikhani-Nahrkhalaji M, et al. Biodegradable nanocomposite coatings accelerate bone healing: In vivo evaluation. Dent Res J (Isfahan). 2015;12(1):89?99.

- Chen Q, et al.Cellulose Nanocrystals–Bioactive Glass Hybrid Coating as Bone Substitutes by Electrophoretic Co-deposition: In Situ Control of Mineralization of Bioactive Glass and Enhancement of Osteoblastic Performance. ACS Appl Mater Interfaces. 2015 Nov 11;7(44):24715?25.

- van Oirschot BA, et al. Comparison of different surface modifications for titanium implants installed into the goat iliac crest. Clin Oral Implants Res. 2016;27(2):e57?67.

- Kaur G, et al D. Review and the state of the art: Sol–gel and melt quenched bioactive glasses for tissue engineering. J Biomed Mater Res B Appl Biomater 2016;104, 1248–1275.

- Karwowska E. Antibacterial potential of nanocomposite-based materials – a short review. Nanotechnology Reviews 2016;6(2):243?254.

- Rivadeneira J and Gorustovich J. Bioactive glasses as delivery systems for antimicrobial agents. Journal of Applied Microbiology 2016;122, 1424–1437.

- Mo Sci Corporation website. http://www.mo-sci.com/en/products